language

Erreur de format d'e-mail

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

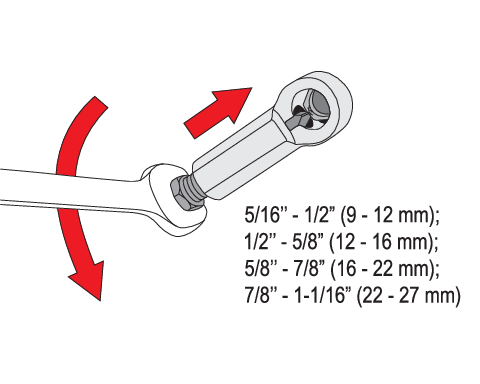

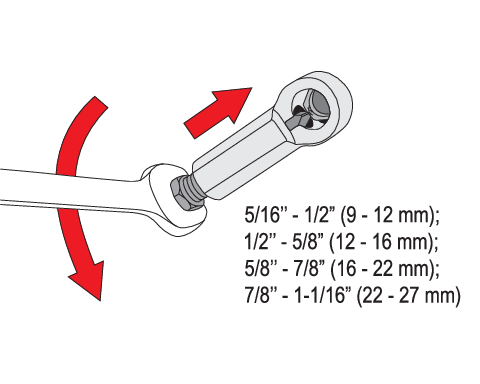

A Heavy Duty Nut Splitter is a robust tool designed for removing stubborn or seized nuts and bolts without causing damage to the surrounding components. It features a strong, durable construction and a sharp cutting blade that can easily slice through tough metal. This tool is ideal for mechanics and DIY enthusiasts who need to tackle rusted or frozen fasteners efficiently, allowing for quick repairs and maintenance in automotive or industrial applications. Its ergonomic design ensures user comfort while maximizing leverage for effective cutting.

Heavy Duty Nut Splitter

Application Area

Automotive Repairs:

Industrial Machinery Maintenance:

Construction and Infrastructure:

Railway Maintenance:

Marine and Offshore Operations:

Agricultural Equipment:

Mining Operations:

Emergency Rescue Operations:

Plumbing and Pipeline Repairs:

DIY and Home Workshops: